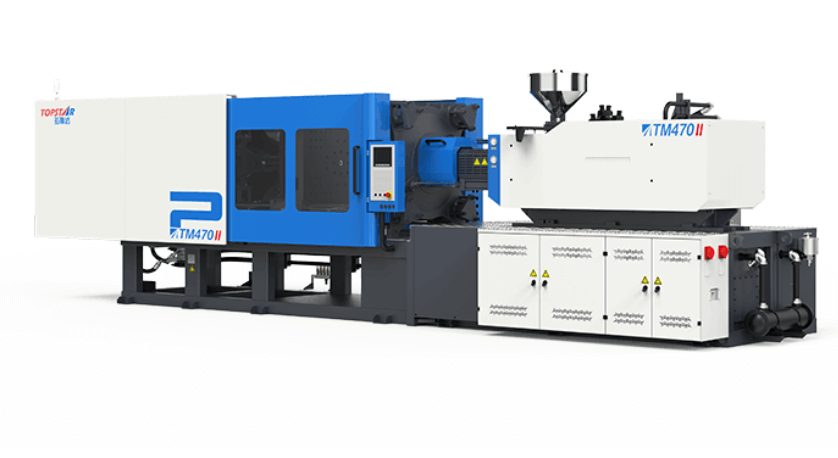

Injection molding machine barrel wear indicators: planning replacement

When it comes to the maintenance of an injection molding machine, the barrel is one of the most critical yet often overlooked components. Over time, the inner surface of the barrel wears due to abrasive wear from resin, fillers, and processing temperatures. Early detection of barrel wear indicators can prevent costly downtime, reduced part quality, and unplanned production stops. Injection molding machine barrel wear is primarily caused by friction between the rotating screw and the steel bore, as well as erosion from additives such as glass fiber or calcium carbonate. As wear progresses, the barrel ID gradually increases in critical areas, resulting in reduced back pressure, poor melt homogeneity, and inconsistent shot weights.

Barrel Inspection and Visual Wear Indicators for Injection Molding Machine

The first step in maintaining injection molding machines is to inspect the barrel for visible signs of wear thoroughly. While technicians rely primarily on performance indicators, visual inspection can provide direct evidence of wear progression. When checking the barrel, it is recommended to remove the screw assembly and illuminate the interior with an endoscope or inspection flashlight. Watch for three main signs of wear: scratches along the inner bore, loss of mirror finish, and pitting. Scratches appear as longitudinal scratches parallel to the screw threads.

They indicate wear caused by filler or recycled resin contamination. At the same time, the once polished surface of the bore begins to dull and take on a “brushed” appearance, especially in the metering section. Pitting appears as localized depressions caused by chemical attack or particle embedment. Also, pay attention to changes in barrel wall thickness, which may indicate severe erosion. After noting these visible changes, record their location and severity.

Injection Molding Machine Barrel Measurement Technology and Wear Quantification

Once visual inspection confirms barrel wear, the following key step in evaluating the wear indicators of injection molding machine barrels is accurate measurement. Quantifying wear enables technicians to determine whether the barrel is within tolerance or requires replacement. The most common method is to use a telescopic bore gauge or a circlip bore gauge to measure the inside diameter at multiple axial locations, including the feed zone, transition zone, and metering zone. First, thoroughly clean the barrel to remove any residual melt or degradation products.

Then, insert the telescopic bore gauge into each section and expand it to contact the inner wall, then lock and remove it for micron measurement. Ideally, the barrel diameter should not change by more than 0.02 to 0.05 mm from the original specification. Exceeding this threshold indicates that the compromised melt seal requires replacement according to a set schedule. For increased accuracy, some advanced machines utilize portable laser ID scanners that can generate 3D maps of the barrel interior and pinpoint high-wear areas with sub-millimeter accuracy.

Process Monitoring as Indirect Barrel Wear Indicators

While visual and dimensional inspections are fundamental, indirect barrel wear indicators often manifest themselves under normal processing conditions, providing early warning of impending problems. For injection molding machines, variables such as injection pressure, back pressure, and melt temperature gradually change as the barrel ID expands. For example, suppose the wear area allows the melt to bypass the screw tip more easily. In that case, the injection pressure sensor will register a lower-than-normal peak value under standard machine settings.

Conversely, an inconsistent melt temperature may indicate recirculation or enlargement of the flow channel. Monitoring weight deviations from shot to shot can also provide clues: when the barrel loses sealing efficiency, shot size may fluctuate at the same screw position command. Many modern injection molding machines utilize centralized process monitoring systems that can record these parameters in real time. By setting alarm thresholds, operators can receive proactive notifications to schedule detailed barrel inspections.

Material Selection and Wear-Resistant Strategies

To mitigate the effects of wear, many injection molding machine manufacturers invest heavily in selecting barrel materials and applying surface treatments that enhance wear resistance. Common base materials include high-strength steel alloys such as 38CrMoAl or 420 stainless steel alloys, which are highly regarded for their toughness and corrosion resistance. In addition to selecting strong base steel, the barrel bore is often coated with a special coating such as WC-Co or Cr₃C₂ deposited by HVOF spraying. These hardened layers have Rockwell hardness values above HRC 60 and can significantly reduce wear caused by glass fiber or mineral-filled resins.

Other surface treatments include plasma nitriding, which diffuses nitrogen into the base material to form a hardened shell up to 0.5 mm thick. Planners should consider the type of resin processed on the injection molding machine, the expected production volume, and any abrasive additives present when they specify a replacement barrel.

Replacement Programs and Lifecycle Cost Considerations

An effective injection molding machine barrel replacement program requires a comprehensive understanding of wear indicators and the financial impact of downtime. Rather than wait for catastrophic barrel failure, savvy manufacturers take a proactive approach Based on measured wear percentages, process performance impacts, and overall equipment effectiveness. For example, if the barrel’s ID wears to 80% of its allowable tolerance, a maintenance manager can order a replacement barrel and schedule machine downtime during a planned preventive maintenance period. To justify the investment, a lifecycle cost analysis comparing the cumulative costs of frequent emergency repairs versus planned replacements often reveals significant savings. Additionally, service contracts with injection molding machine OEMs or third-party engineering firms typically include barrel replacement kits, which streamline the replacement process and reduce machine downtime from days to hours.

Planned Barrel Wear Replacement

Injection molding machine barrel wear indicators are essential signals to guide maintenance decisions, helping manufacturers avoid costly unplanned downtime. By combining direct methods with indirect process monitoring, industry professionals can detect wear patterns early and develop replacement plans tailored to their specific circumstances. Additionally, selecting high-quality barrel materials and utilizing advanced surface treatment technologies can enhance wear resistance, extend maintenance intervals, and reduce lifecycle costs.